SF6 Gas Insulated Switchgear is a high-voltage electrical equipment that uses sulfur hexafluoride (SF6) gas as an insulating and arc-extinguishing medium. Its core components (such as circuit breakers, disconnectors, busbars, etc.) are sealed in a metal casing filled with SF6 gas. The SF6 switchgear encapsulates all high-voltage parts in a gas tank, which not only ensures the safety of operators but also has moisture-proof and dust-proof functions, extending the service life of the equipment. TSTY's SF6 switchgear mainly has 6kV, 10kV, 15kV, 20kV, 33kV and other specifications, and is widely used in cities, industrial areas, power generation and transmission, data centers and factories.

SF6 Switchgear Parameters

|

|

C module |

F module |

V module |

CB module |

|||

|

|

|

Load switch |

Combination electric appliance |

vacuum switch |

Isolation/grounding switch |

Direct-air circuit breaker |

Isolation/ grounding switch |

|

Rated Voltage |

KV |

12 |

12 |

12 |

12 |

12 |

12 |

|

Rated Frequency |

HZ |

50 |

50 |

50 |

50 |

50 |

50 |

|

Power Frequency Withstand Voltage (phase/fracture) |

KV |

42/48 |

42/48 |

42/48 |

42/48 |

42/48 |

42/48 |

|

Lightning shock withstand voltage |

KV |

75/85 |

75/85 |

75/85 |

75/85 |

75/85 |

75/85 |

|

Rated current |

A |

630 |

Note 1 |

630 |

|

1250/630 |

|

|

Rated closed loop breaking current |

A |

630 |

|

|

|

|

|

|

Rated cable charging break current |

A |

10 |

|

|

|

|

|

|

Rated short circuit closing current (peak) |

A |

50 |

80 |

|

|

|

|

|

Rated peak tolerable current |

kA |

50 |

|

|

|

|

|

|

Rated short-time tolerable current |

kA/ 3s |

20 |

|

|

|

|

|

|

Rated short circuit breaking current |

kA |

|

31.5 |

20 |

|

25 |

|

|

Rated transfer current |

A |

|

1700 |

|

|

|

|

|

Use the maximum current of the fuse |

A |

|

125 |

|

|

|

|

|

Loop resistance |

-n |

≤300 |

≤600 |

|

|

|

|

|

Mechanical life |

Times |

5000 |

3000 |

5000 |

2000 |

5000 |

2000 |

Product Features

1. Good insulation performance: SF6 gas has high insulation strength, which is more than three times that of air under the same pressure. It can effectively reduce electrical gaps and make the equipment structure more compact.

2. Strong arc extinguishing ability: SF6 has good arc extinguishing performance, which is 100 times that of air. It can quickly extinguish arcs, improve the breaking capacity and reliability of switchgear, and is suitable for occasions with frequent operations.

3. The cabinet is constructed of 316L stainless steel with a nano-ceramic coating, has passed 3000 hours of salt spray and 200 cycles of hot and cold cycling, and boasts high UV resistance standards, with a 30-year warranty.

4. Equipped with advanced Schneider vacuum circuit breakers or high-quality domestic vacuum circuit breakers, it offers superior performance.

5. The enclosure has an IP4X protection rating, maintaining IP2X even when the circuit breaker compartment door is open.

6. The product features comprehensive "five-protection" interlocking features to ensure operator safety.

7. The main busbar current rating is 4000A, the short-circuit breaking current is 50kA, and the mechanical life is 20,000 cycles.

SF6 Gas Insulated Switchgear Application Scenarios

Urban power grid: dense urban areas, underground substations and other areas with limited space, using its compactness to optimize layout.

Special environments: industrial pollution areas, high humidity coastal areas, multiple earthquake zones and other places with high requirements for equipment reliability.

New energy grid connection: in the booster stations of wind farms and photovoltaic power stations, adapting to frequent operations and complex grid conditions.

Precision Manufacturing System

1. Micron-level precision manufacturing

Equipped with ±0.1mm high-precision industrial robots, it realizes millimeter-level control of switch cabinet bending and assembly, with a standardization rate of parts ≥99% and a size qualification rate of over 99.5%.

2. German imported spraying system

Adopting electrostatic spray guns and water-based environmentally friendly paint, the coating uniformity error is ≤5μm, VOC emissions are reduced by 80%, and "zero-defect appearance" and green manufacturing are achieved simultaneously. The spraying defect rate is controlled within 0.3%.

3. Fully automated production

Relying on Schneider's benchmark intelligent production line, a fully automated production model is created, manual intervention is reduced by 70%, the production cycle of a single cabinet is compressed to 30 minutes, and the production capacity is increased by 30%.

Full Automatic Production Line

Relying on Schneider's benchmark intelligent production line, we have created a fully automated production model of "the cabinet moves but the people do not move". Manual intervention is reduced by 70%, the production cycle of a single cabinet is compressed to 30 minutes, the production capacity is increased by 30%, and the process is fully benchmarked against IEC/GB international standards. From precision manufacturing to environmental protection upgrades, we use the dual-wheel drive of "technology + efficiency" to ensure that each switch cabinet has both industrial aesthetics and ultra-long life to meet the needs of global high-end power projects.

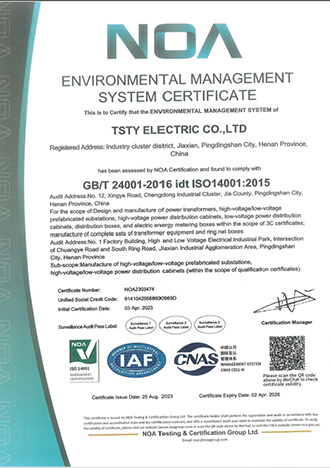

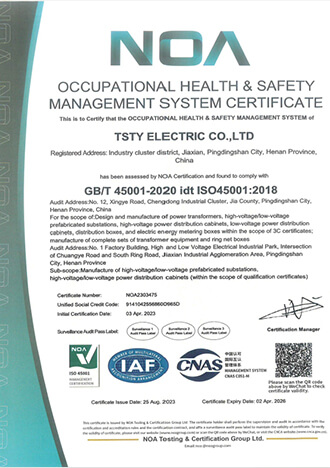

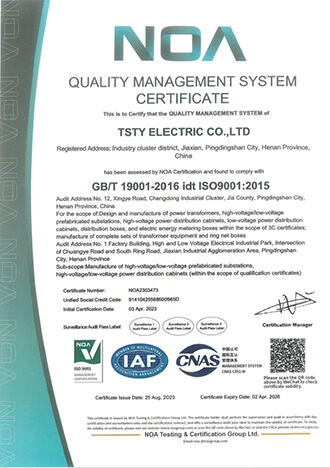

About TSTY

TSTY Electric - a national high-tech enterprise with more than 30 years of history, focuses on the intelligent manufacturing of power transmission and distribution equipment, and mainly deals in oil-immersed/dry-type transformers, box-type substations, and high and low voltage switchgear.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.