Brand Name: TSTY

Model Number: KYN28

KYN28A-12 is a common high-voltage switchgear with a rated voltage of 3.6kV to 12kV. Rated current up to 3150A, AC 50/60HZ. This switchgear is suitable for receiving and distributing electric energy, as well as controlling, protecting and measuring circuits. It is widely used in power plants, substations, power distribution centers of industrial and mining enterprises, etc.

Main Technical Parameters

Main Technical Parameters|

No. |

Item |

Unit |

Data |

||

|

1 |

Rated voltage |

kV |

3.6, 7.2, 12 |

||

|

2 |

Rated frequency of circuit breaker |

Hz |

50 |

||

|

3 |

Rated current of circuit breaker |

A |

630, 1250, 1600, 2000, 2500, 3150, 4000 |

||

|

4 |

Rated current of switchgear |

A |

630, 1250, 1600, 2000, 2500, 3150, 4000 |

||

|

5 |

Rated short-time withstand current (4s) |

kA |

16, 20, 25, 31.5, 40, 50 |

||

|

6 |

Rated withstands current (peak) |

kA |

40, 50, 63, 80, 100, 25 |

||

|

7 |

Rated short-circuit breaking current |

kA |

16, 20, 25, 31.5, 40, 50 |

||

|

8 |

Rated short-circuit closing current (peak) |

kA |

40, 50, 63, 80, 100, 25 |

||

|

9 |

Rated insulation level |

1 min power frequency withstands voltage |

between poles, pole to earth |

kV |

24, 32, 42 |

|

between open contacts |

kV |

24, 32, 48 |

|||

|

Lightening impulse withstands voltage (peak) |

between poles, pole to earth |

kV |

40, 60, 75 |

||

|

between open contacts |

kV |

46, 70, 85 |

|||

|

10 |

Protection level |

|

Shell: IP4X; IP2X when the CPT and CB doors are open |

||

Note: 1. The short circuit capacity of the current transformer should be separately considered.

2. See technical parameters of ZN63A-12 in related catalogues of our company.

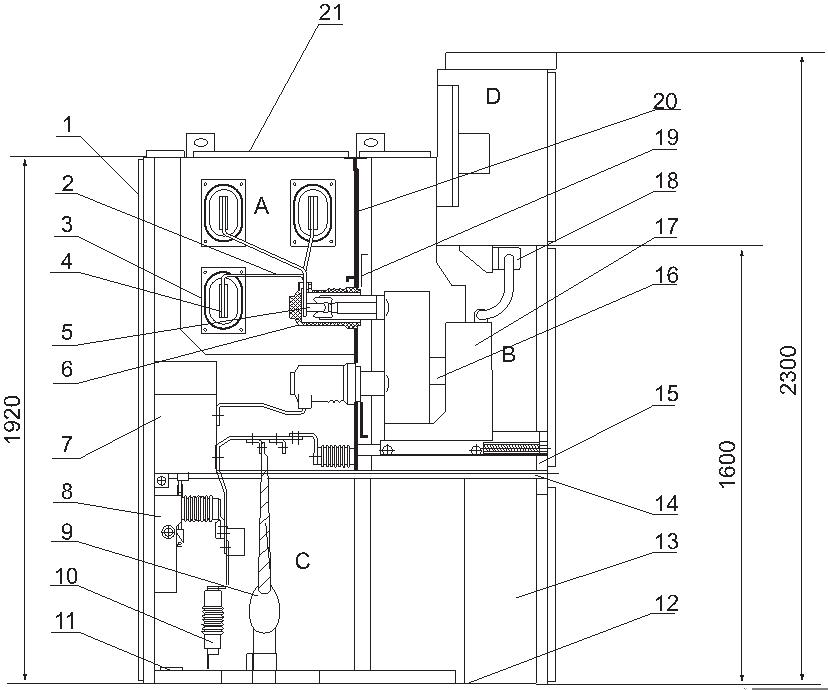

Structural Diagram of Switchgear

Structural Diagram of Switchgear

Product Features

Product Features1. Equipped with a ±0.1mm high-precision industrial robot, it achieves millimeter-level control of switchgear bending and assembly, achieving a component standardization rate of ≥99% and a dimensional qualification rate exceeding 99.5%.

2. The cabinet body is constructed from 316L stainless steel with a nano-ceramic coating, processed and formed, and assembled using high-strength bolts, nuts, and rivets.

3. Compatible with various brands of circuit breakers, including components from brands such as ABB and Siemens, including the domestically produced ZN85-40.5 (3AV3) vacuum circuit breaker and Schneider's HVX series, to meet diverse user needs.

4. Each functional compartment in the switchgear is separated by metal partitions and equipped with independent pressure relief ducts.

5. Circuit breaker, earthing switch, and other operations can be performed with the high-voltage compartment door closed, allowing for closed-door operation.

6. Full-Scenario Verification and Intelligent Logistics System: Cabinet Parallel Testing - Real-World Simulation. Full-Scenario Simulation Testing: Load Simulation, Emergency Operation Verification (Opening and Closing Response Time ≤ 20ms) Multi-Device Linkage Testing (Protection Device/Transformer Coordination Error <1%) Triple Performance Verification: Passed a 72-hour full-load temperature rise test and a mechanical lifespan test of ≥10,000 cycles

Strict Quality Control

Strict Quality Control

Full-link intelligent detection technology:

Real-time monitoring of key states: infrared temperature measurement technology, partial discharge monitoring, intelligent sensor network, three-level quality firewall,

100% spectral detection of raw materials, 20+ key points in the production process, 72 hours of full project experiment before leaving the factory.

R&D Advantages

R&D AdvantagesTSTY currently has 600 employees and a technical R&D team of more than 200 people. It has established a science and technology innovation center to focus on material and process innovation and realize independent research and development of transformers; relying on the national CNAS certified laboratory, each product passes more than ten rigorous tests such as lightning strike and insulation no-load loss to ensure stable operation in the whole environment.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.