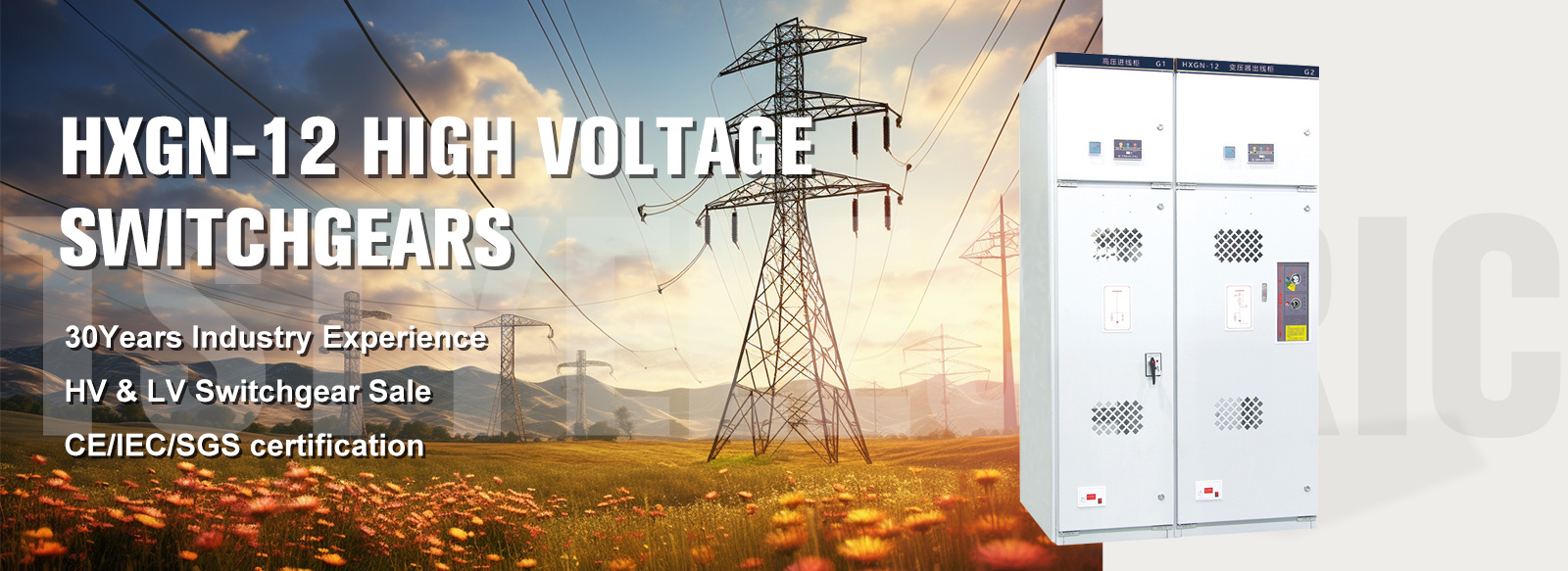

HXGN modular high-voltage switchgear is suitable for receiving and distributing electric energy in three-phase AC power systems with rated voltages of 3, 6, 10KV and rated frequency of 50HZ. The switchgear complies with the requirements of national standard GB3906 and international standard IEC298. It is widely used in power distribution in urban residential areas, small secondary distribution stations, shopping malls, subways, power stations, etc.

HXGN-12 Switchgears Parameters

HXGN-12 Switchgears Parameters|

Item |

Unit |

Load Switch Cabinet |

Combined Electrical Cabinet |

||

|

Rated voltage |

|

|

KV |

12 |

|

|

Reted power |

|

|

Hz |

50/60 |

|

|

Rated insulation level |

1 min power frequency withstand voltage |

Alternately and relatively |

KV |

42 |

|

|

Isolation fracture |

48 |

||||

|

Lightning impulse withstand voltage |

Alternately and relatively |

75 |

|||

|

Isolation fracture |

85 |

||||

|

Rated current of main bus |

A |

630 |

125 |

||

|

Rated shore-time withstand current |

KA/4S |

20 |

20 |

||

|

Rated peak withstand current |

KA |

50 |

50 |

||

|

Rated AC current |

A |

|

3150 |

||

|

Rated short-circuit making current (peak value) |

KA |

50 |

50 |

||

|

Rated short-circuit breaking current (effective value) |

KA |

|

31.5 |

||

|

Rated active load breaking current |

A |

630 |

|

||

|

Ground loop dynamic stability current (peak value) |

KA |

50 |

|||

|

Ground loop thermal stability current |

KA/2 |

20 |

|||

|

Mechanical life |

Vacuum load switch |

Time |

10000 |

||

|

Earthing switch |

Time |

2000 |

|||

|

Auxiliary circuit 1min power frequency withstand voltage |

KV |

2 |

|||

|

Working voltage of electric operating mechanism |

V |

AC220/110;DC220/110 |

|||

|

Enclosure rating |

|

IP2X、IP3X |

|||

Core Advantages Of Digital Production Lines

Core Advantages Of Digital Production Lines1. Using the dual engines of "data + intelligence" to drive manufacturing innovation and build an industry-leading digital production system.

2. Relying on 220+ sets of intelligent equipment clusters, unmanned operation of the entire process from sheet metal processing to finished product assembly is realized, the manual intervention rate of key processes is less than 5%, and the yield rate exceeds 99.8%.

3. The U-shaped layout and modular design increase material handling efficiency by 40%, produce 10,000 high and low voltage equipment each year, and shorten the order delivery cycle by 30%.

4. AGV logistics and digital twin systems are linked to achieve 72 hours of unmanned continuous operation, and the capacity utilization rate reaches more than 95%.

5. Green manufacturing, waste recovery rate exceeds 90%, noise and emission indicators are 20% better than the national standard, and it has been rated as a provincial smart factory benchmark.

Intelligent Warehousing System

Intelligent Warehousing System

About TSTY

About TSTYTSTY Electric Co., Ltd is a national high-tech enterprise with a history of more than 30 years, focusing on the intelligent manufacturing of power transmission and distribution equipment. It mainly deals in oil-immersed, dry-type transformers, box-type substations, high and low voltage switchgear and have obtained ISO 9001, CCC, CE, IEC, GOST and other certifications, 158 patents, and are exported to more than 80 countries. Factory scale: 250,000 square meters of park, 15 production lines (including 3 intelligent lines), equipped with 220+ intelligent equipment. Production capacity efficiency: annual output value of 1.5 billion yuan, product qualification rate> 99.8%.

Customization And Testing Capabilities

Customization And Testing Capabilities1. Deep customization service Modular design solution:

Supports free selection of brand components such as ABB/Siemens; supports appearance customization, up to 20+ colors, ODM/OEM full mode coverage.

2. International testing laboratory

Each switch cabinet has passed a variety of tests such as short-circuit test platform, temperature rise test chamber (-40℃~+150℃), partial discharge detection system (accuracy 0.1pC), etc.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.