Brand Name: TSTY

Model Number: S11-S22

Phase: Three

Service Voltage: 6kV 11KV 20KV

Rated Capacity: 15-31500kVA

Our company's oil-immersed transformer series has become a leader in the field of power supply due to its excellent performance, safety and stability, as well as durability. The product line covers various models from S9 to S22, suitable for voltage ranges from 6kv to 35kv, with a capacity ranging from 15kva to 31500kva, meeting the needs of various scenarios.

TSTY Transformer Advantage

TSTY Transformer AdvantageSilicon steel sheet: Use the best silicon steel sheets from Baosteel and Wuhan Iron and Steel in China, with high quality, high permeability and low loss;

Conductive rod: Highly conductive H62 material, effectively reducing heat generation and ensuring equipment stability;

Insulation system: New mineral insulating oil, enhanced insulation/extended life;

Tansformer box: Made of national standard high-quality steel plate profile, mechanical strength ≥345MPa, durable life >30 years.

6-22kv Transformer Parameters

6-22kv Transformer Parameters

| S11 6-11kV Oil Immersed Transformer Main Technical Parameters | |||||||||||||

| Rated Capacity KVA | Voltage Combination | Connection Symbol | Off-load Loss(W) | On-load Loss(W) (75℃) | Short Circuit Impendan ce(%) | Impendance (%) | Weight(KG) | Dimensions(mm) | |||||

| High Voltage (KV) | Tapping Range (%) | Low Voltage (KV) | Oil | Total | Length | Width | Height | ||||||

| 30 |

6 6.3 10 10.5 11 |

±5 ±2x2.5 |

0.38 0.4 0.415 0.433 |

Dyn11 Yyn0 | 90 | 600 | 2.1 | 4 | 60 | 285 | 715 | 595 | 800 |

| 50 | 120 | 870 | 2 | 65 | 360 | 760 | 810 | 830 | |||||

| 63 | 140 | 1040 | 1.9 | 100 | 500 | 1080 | 620 | 1090 | |||||

| 80 | 170 | 1250 | 1.8 | 80 | 455 | 975 | 640 | 880 | |||||

| 100 | 200 | 1500 | 1.6 | 90 | 525 | 970 | 640 | 910 | |||||

| 125 | 235 | 1800 | 1.5 | 95 | 580 | 1050 | 700 | 940 | |||||

| 160 | 280 | 2200 | 1.4 | 110 | 680 | 1160 | 785 | 960 | |||||

| 200 | 335 | 2600 | 1.3 | 125 | 765 | 1125 | 770 | 1000 | |||||

| 250 | 390 | 3050 | 1.2 | 140 | 860 | 1200 | 835 | 1020 | |||||

| 315 | 465 | 3650 | 1.1 | 155 | 1005 | 1305 | 910 | 1050 | |||||

| 400 | 560 | 4300 | 1.0 | 175 | 1170 | 1305 | 900 | 1090 | |||||

| 500 | 670 | 5100 | 1.0 | 210 | 1370 | 1410 | 1015 | 1140 | |||||

| 630 | 840 | 6200 | 0.9 | 4.5 | 260 | 1700 | 1545 | 1095 | 1160 | ||||

| 800 | 980 | 7500 | 0.8 | 305 | 2025 | 1590 | 1130 | 1200 | |||||

| 1000 | 1190 | 10300 | 0.7 | 375 | 2290 | 1680 | 1230 | 1300 | |||||

| 1250 | 1360 | 12000 | 0.6 | 445 | 2680 | 1715 | 1245 | 1400 | |||||

| 1600 | 1640 | 14500 | 0.6 | 520 | 3160 | 1785 | 1290 | 1500 | |||||

| 2000 | 1980 | 18500 | 0.5 | 5 | 785 | 4020 | 1850 | 1315 | 1530 | ||||

| 2500 | 2450 | 23500 | 0.45 | 5 | 925 | 4810 | 1945 | 1370 | 1610 | ||||

| S11 20KV Oil Immersed Transformer Main Technical Parameters | |||||||||||||

| Rated Capacity KVA | Voltage Combination | Connection Symbol | Off-load Loss(KW) | On-load Loss(KW) (75℃) | Short Circuit Impendan ce(%) | Impendan ce (%) | Weight(KG) | Dimensions(mm) | |||||

| High Voltage (KV) | Tapping Range (%) | Low Voltage (KV) | Oil | Total | Length | Width | Height | ||||||

| 30 |

20 22 24 |

±5 ±2x2.5 |

0.23 0.38 0.4 0.44 0.48 0.6 |

Dyn11 Yyn0 |

0.1 | 0.66 | 2.1 | 5.5 | 75 | 350 | 1040 | 600 | 1040 |

| 50 | 0.13 | 0.96 | 2 | 90 | 445 | 1040 | 600 | 1085 | |||||

| 63 | 0.15 | 1.145 | 1.9 | 100 | 500 | 1080 | 620 | 1090 | |||||

| 80 | 0.18 | 1.37 | 1.8 | 105 | 535 | 1110 | 640 | 1110 | |||||

| 100 | 0.2 | 1.65 | 1.6 | 120 | 580 | 1235 | 800 | 1210 | |||||

| 125 | 0.24 | 1.98 | 1.5 | 125 | 660 | 1245 | 810 | 1220 | |||||

| 160 | 0.29 | 2.42 | 1.4 | 130 | 700 | 1265 | 830 | 1230 | |||||

| 200 | 0.33 | 2.86 | 1.3 | 195 | 835 | 1140 | 720 | 1330 | |||||

| 250 | 0.4 | 3.35 | 1.2 | 410 | 1110 | 1325 | 850 | 1490 | |||||

| 315 | 0.48 | 4.01 | 1.1 | 420 | 1610 | 1380 | 850 | 1725 | |||||

| 400 | 0.57 | 4.73 | 1 | 430 | 1720 | 1400 | 885 | 1810 | |||||

| 500 | 0.68 | 5.66 | 1 | 480 | 1940 | 1500 | 890 | 1850 | |||||

| 630 | 0.81 | 6.82 | 0.9 | 6 | 490 | 2055 | 1645 | 970 | 1850 | ||||

| 800 | 0.98 | 8.25 | 0.8 | 520 | 2600 | 1755 | 1025 | 1890 | |||||

| 1000 | 1.15 | 11.33 | 0.7 | 585 | 2870 | 2270 | 1060 | 1890 | |||||

| 1250 | 1.35 | 13.2 | 0.6 | 620 | 3560 | 2400 | 1120 | 2040 | |||||

| 1&00 | 1.63 | 15.95 | 0.6 | 690 | 4260 | 2460 | 1220 | 2085 | |||||

| 2000 | 1.95 | 19.14 | 0.6 | 860 | 5550 | 2480 | 2400 | 2940 | |||||

| 2500 | 2.34 | 22.22 | 0.5 | 990 | 6320 | 2480 | 2620 | 3040 | |||||

Our R&D Advantages

Our R&D AdvantagesTSTY currently has 600 employees and a technical R&D team of over 200 people. It has established a science and technology innovation center to focus on material and process innovation and realize independent research and development of transformers. Relying on the national CNAS certified laboratory, each product passes more than ten rigorous tests such as lightning impulse and insulation no-load loss to ensure stable operation in all environments.

Project Case

Project CaseOur products are exported to more than 80 countries and regions, serving power projects in various regions.

About TSTY

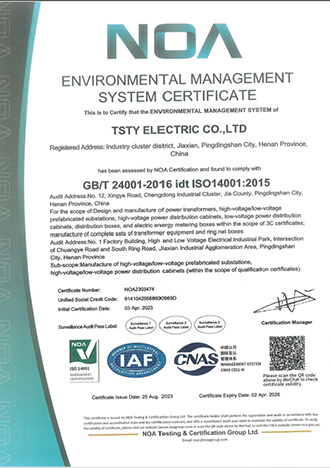

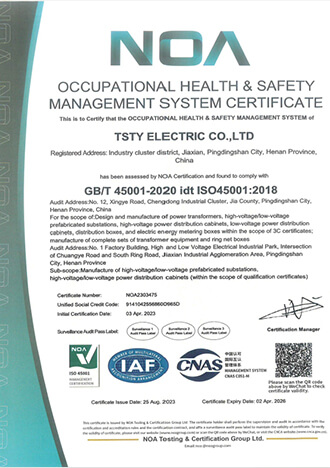

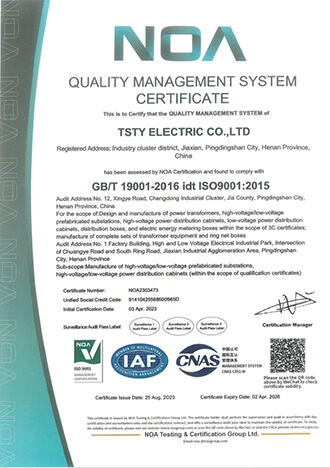

About TSTYTSTY Electric Co., Ltd is a national high-tech enterprise with a history of more than 30 years, focusing on the intelligent manufacturing of power transmission and distribution equipment. It mainly deals in oil-immersed, dry-type transformers, box-type substations, high and low voltage switchgear and have obtained ISO 9001, CCC, CE, IEC, GOST and other certifications, 158 patents, and are exported to more than 80 countries. Factory scale: 250,000 square meters of park, 15 production lines (including 3 intelligent lines), equipped with 220+ intelligent equipment. Production capacity efficiency: annual output value of 1.5 billion yuan, product qualification rate> 99.8%.

To Be Our Agent

To Be Our Agent

Want to be our agent?

Welcome to join the TSTY agent team! As TSTY's influence at home and abroad gradually increases, our overseas business market has also been greatly expanded. We sincerely invite you to join us in expanding overseas markets. Let us work together to let green electricity change the world.

Join our agent team, you will enjoy the following advantages and support:

High-quality products: Our products are manufactured with international advanced technology and quality assurance, and we provide quality assurance for the transformer products provided, providing customers with stable and efficient power transmission solutions.

Stable product supply: TSTY will ensure sufficient and stable supply, and deliver goods in a timely and accurate manner according to the order requirements of agents. Avoid sales losses due to out-of-stock, and ensure that the agent's business can be carried out stably and continuously.

Brand support: As a TSTY agent, you will receive our strong brand support and marketing promotion to help you establish a good reputation and position in the local market.

Technical support: We will provide dealers with comprehensive pre-sales, in-sales and after-sales services, including full-scale technical support for communication with customers, sales and product installation, commissioning and use.

Training support: TSTY supports agents to provide professional and comprehensive product knowledge training, technical service training, etc., to ensure that agents can serve customers more professionally and independently.

Generous returns: We will provide agents with competitive pricing policies and sales commissions to share market results.

If you are interested in becoming a TSTY agent, please call the official phone number +86 15890606007, or send an email to info@tstyelectric.com to obtain the agency agreement. We look forward to working with you to create a better future!

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.